-

HOME

-

PRODUCTS

- High Speed Area Scan Camera

-

COAXPRESS SERIES-29MM CXP 1LANE SERIES

-

COAXPRESS SERIES-40MM CXP 1LANE SERIES

-

COAXPRESS SERIES-60MM CXP 4LANE SERIES

-

COAXPRESS SERIES-70MM CXP 4LANE SERIES

-

PIXEL SHIFT

-

SWIR Area Scan Camera

-

Camera Link Series

-

21MP CXP-12X4Lane Model

-

SOLUTIONS

-

SUPPORT

-

ABOUT US

-

CONTACT

- SOLUTION

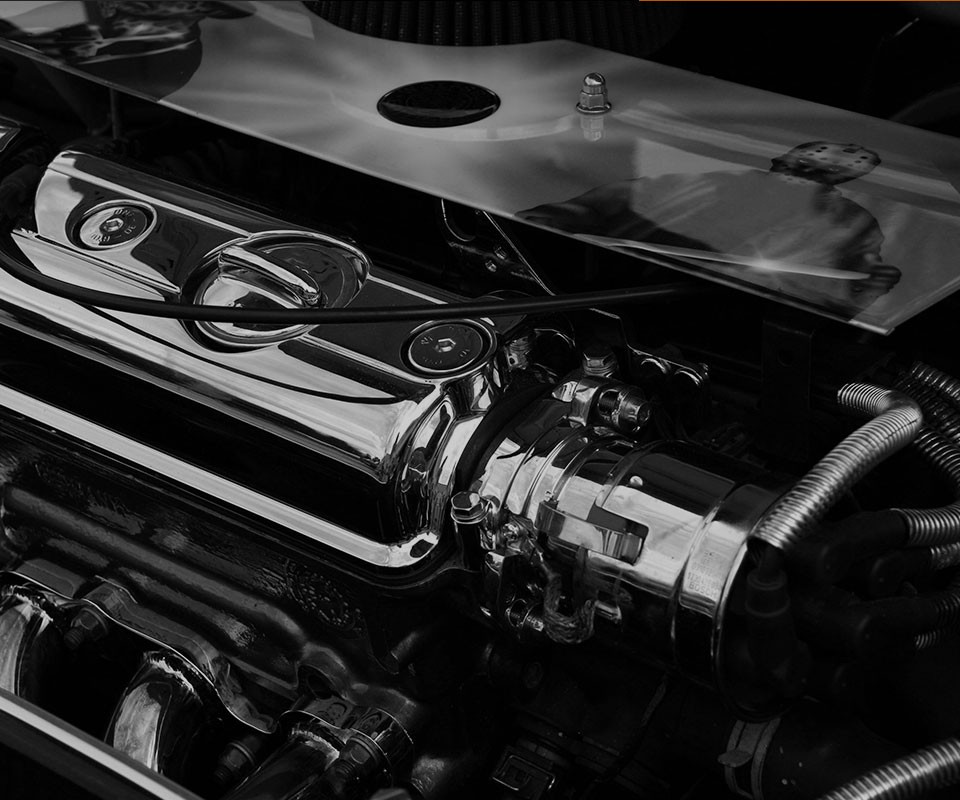

Automotive Industry Solutions SOLUTIONS

Automotive Industry Solutions SOLUTIONS

- Summary

- Grabbing and polishing the cylinder head workpiece needs to overcome the unfavorable factors of on-site ambient light interference and a certain degree of reflection on the surface of the workpiece. The structured light 3D camera and 3D vision guidance system independently developed by Boshi Pixel can quickly and accurately grab the workpiece without manual operation.

- Industry Overview

- In the automobile engine production line, the automatic loading of the engine cylinder head is the first step in all assembly production. With the development of industrial automation, labor costs continue to increase, and the low efficiency of manual loading and handling, high production costs seriously affect the production cycle, and are prone to safety accidents. Improving production efficiency, reducing labor costs, and overcoming the unfavorable factors of ambient light interference in the auto parts industry have become urgent problems to be solved.

Solution Overview

Solution Overview

To grab the cylinder head workpiece, there must be direction information. The site needs to overcome the unfavorable factors of ambient light interference and a certain degree of reflection on the surface of the workpiece.

The structured light 3D camera and 3D vision guidance system independently developed by BoPixel can quickly and accurately capture the workpiece without manual operation, and automatically complete the production task according to the production task plan.

The structured light 3D camera and 3D vision guidance system independently developed by BoPixel can quickly and accurately capture the workpiece without manual operation, and automatically complete the production task according to the production task plan.

Solution Difficulties

Solution Difficulties1

Manual grasping and polishing affect the production pace, there are hidden quality problems and low production efficiency;

2

The visual accuracy of the gripper is required to be 0.5mm, and the site needs to overcome the interference of ambient light and the surface of the workpiece to a certain extent;

3

Unfavorable factors of reflection, otherwise it will damage the workpiece;

4

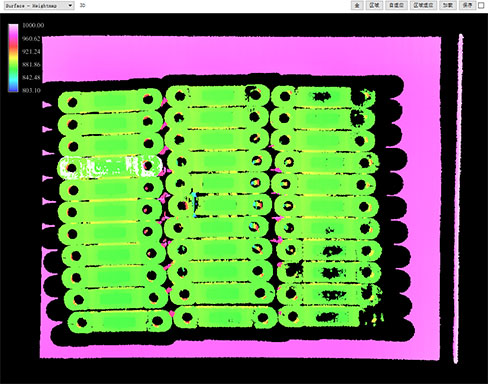

According to the protruding position of the workpiece center, the front and back of the workpiece can be judged, and various types of workpieces can be quickly and accurately grasped;

5

The vision system judges the falling and fallen workpiece, and the system gives an alarm message;

6

The workpieces in the material frame are screened in multiple la yers, and a pallet is stacked in multiple rows, columns, and la yers;

Solution Advantage

Solution Advantage

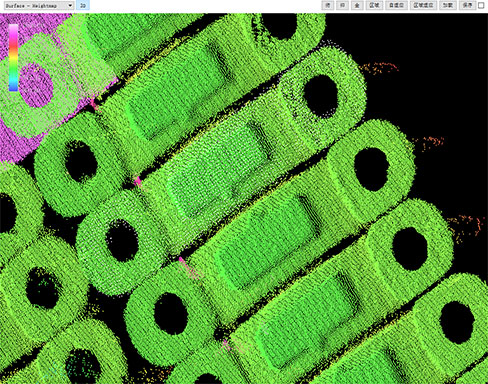

High precision

Independently developed structured light 3D camera RINDO HF series, millimeter-level measurement accuracy,

2 million point cloud data;

2 million point cloud data;

Super brightness

Resist strong light interference and extremely weak light environment and the influence of a certain degree of reflection on the surface of the workpiece;

High adaptability

em bedded GPU, supports AI expansion, compatible with mainstream robots, easy to use;

Large field of view

Up to 3 meters, covering mainstream vision requirements;

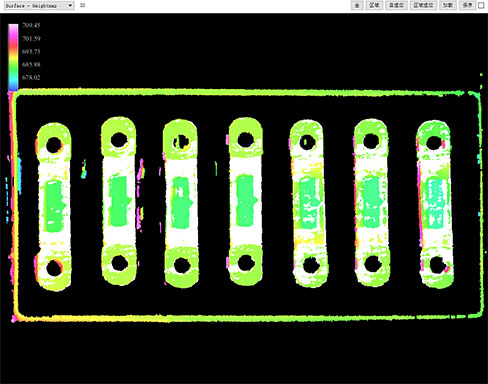

Shooting Effect

- CONTACT INFORMATION

-

Address: 6 / F, Jingdong Technology Building, 76 Zhichun Road, Haidian District, Beijing

Telephone: 010-64754979

- Sales Consulting

-

E-Mail: sales@bopixel.com

Telephone: 139 1010 6272 Mr. Wang

- Technical Support

- E-Mail: support@bopixel.com

- PRODUCTS

- Structured Light 3D Camera

- High Speed Area Scan Camera

- HIGH SPEED LINE SCAN CAMERA

- DLP Projector

- Cr Series Code Reader & Industrial Smart Camera

- Ultra-high speed camera

- Line Laser 3D Profiler

- Frame Grabber

© 2023 Copyright Beijing BOPIXEL Technology Co., Ltd.Beijing Icp No. 2022013801